Vanilla is the most common flavouring in the world. Because of its versatile qualities, it is suitable for many different applications and is therefore used in the manufacturing and flavouring processes of many products, even if they do not have a distinct vanilla flavour.

In nature, vanillin occurs in multiple different plants, and its inherent antibacterial qualities protect the plants from fungi, bacteria and insects. For that reason, vanillin acts as a preservative when used in manufacturing food, fragrances and cosmetic products. The flavoursome vanilla beans have approximately 200 flavour-carrying molecules.

The compound vanillin, primarily responsible for the flavour, can be extracted from vanilla beans or manufactured synthetically. Because the most important source of vanilla beans, Vanilla planifolia, can only be grown in very specific subtropical conditions, manufacturing vanillin synthetically ensures that the high global demand can be met.

The synthetic manufacturing of vanillin became common in the 1970s, when a more cost‑efficient ingredient for manufacturing vanillin – guaiacol – was found. In nature, the organic compound occurs in many different plants and flowers. The molecular structure of guaiacol is very similar to that of vanillin, which makes manufacturing synthetic vanillin out of guaiacol easy. However, because guaiacol is mainly derived from crude oil, it has a negative impact on the environment.

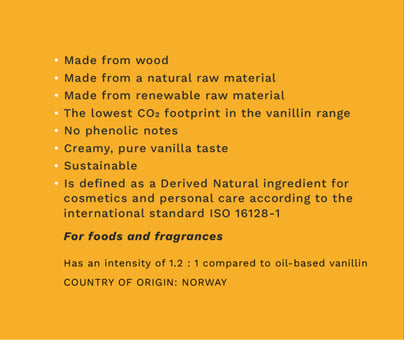

Vanillin can also be synthetically manufactured from other raw materials. One of the most prominent alternative raw materials is wood, from which lignin-based vanillin can be derived. Haarla’s business partner Borregaard has produced lignin-based vanillin since the 1960s, and Borregaard’s 100% wood-based EuroVanillin Supreme is the only PEFC-certified vanillin product on the market.

While the trees are growing, they capture and store carbon dioxide from the atmosphere, and the ready vanillin product is an excellent alternative for guaiacol-based vanillin. Furthermore, for every harvested tree, multiple new ones are planted, thus making the entire production chain sustainable.

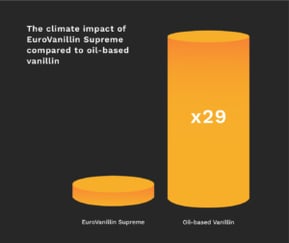

The lignin-based vanillin is plant-based and produced out of completely renewable raw materials, and gives a 90% reduction in carbon dioxide emissions compared to guaiacol-based vanillin. In addition to being more environmentally friendly, the taste profile of EuroVanillin Supreme is creamier than that of crude oil-based vanillin, which helps improve the flavour of the final products.

Versatility guarantees a wide variety of applications

Vanillin is used to flavour many different foods, such as sweets and ice creams, as well as beverages – also when vanilla is not the primary flavour. Vanillin helps create a creamier taste profile, which enhances the products’ flavour and thus has a positive impact on customer satisfaction.

Vanillin can also be used to round out other flavours and to mask unwanted flavours. Therefore, the versatility of vanillin guarantees a wide variety of applications. Apart from the 100% plant-based EuroVanillin Supreme, Borregaard’s product range includes ethyl vanillin, products that combine ethyl vanillin and lignin-based vanillin, as well as tailor-made vanillin products for specific food industry needs.

Haarla – The expert at your side